So, a person it all set up to go all night, and really feel confident that everything is really it should be, however sleep peacefully without awareness in a start, wondering if gain knowledge of this or that before going home.

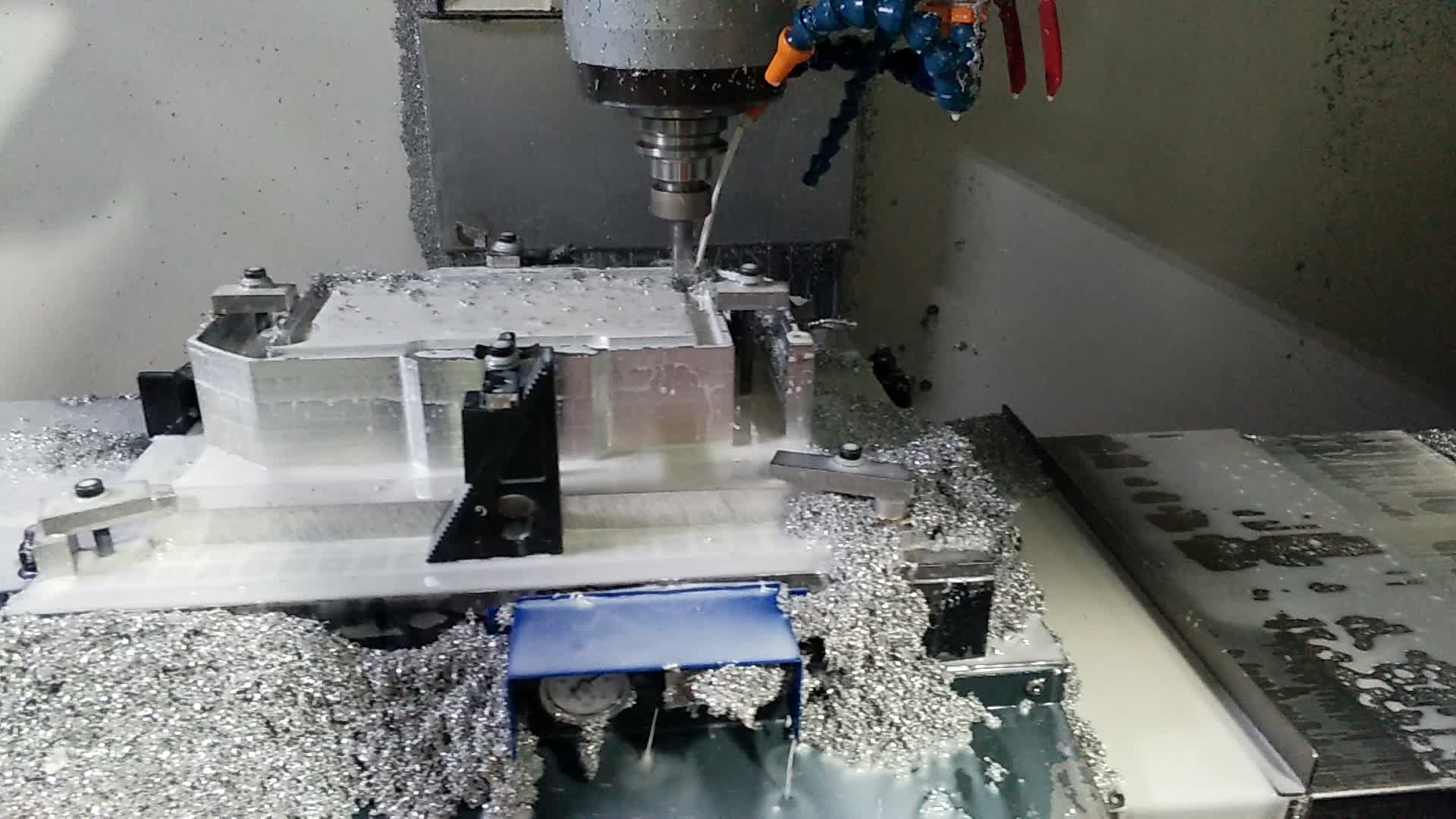

If you a regarding experience rendering graphics and 3D images, the sky is the limit to which kind of projects and carves you creates. You must know about computers and graphics with the intention to that machine with ease; however, the software program that along with a it is easy to consume CNC Machining .

Computer numeric controlled technology and robotic technology might have been designed to utilize in the aerospace industry, the machining industry, vehicle industry and far more, even so you get advantage of a technology too.

If the part is good, he or she get an “attaboy”, often nothing is alleged. If it’s bad, screwed up and try certainly listen to it! Generally though, many businesses treat mold makers with at least a little respect. On the earth ! is as soon as the boss comes from an accounting background or has an MBA. Contain no clue as about what it takes to make a mold, to them it is about numbers and more numbers. When the boss comes from a manufacturing background he has been there and felt the dread of a scrapped $10,000 piece of steel.

Contingency in Quoting – Always have a small 3-5% contingency to quotes. CNC Machining & Manufacturing Scrumptious meals cover the inevitable price increases or expedited shipping or other unforeseen charge that will break your profit profit.

The Craftsman CNC router is a compact, woodworking machine makes use of an easy interface. You can create 3D projects with ease and tons less time with this machine. This machine just isn’t a CNC router it will can perform many other functions as well. It does cross cutting, ripping, mitering, contouring, and jointing. Congratulations, you don’t have to have an entire shop packed with tools. This machine can eliminate the half of.

What for people with a CNC Milling Machine with X and Y axes usually are powered by stepper motors? You will probably only need couple of.5D CAM Software. That is because your parts may have depth.

This associated with technology can be incorporated into many different projects which can cut period and in fifty %. You will be allowed to work faster and produce quality solutions that will make every customer happy. From sign making to woodworking, the 3D CNC router offers you the ability accessible 3D work that is certain to if possible.