cnc machine 24 x 48

How an individual understand task of this machine? A drilling press drills slots. But then own to loosen the chuck, install the drill bit, drill the hole with precision in position place and also the end of it all remove the drill tiny bit. This is the manual way to drilling. On the big scale this is going to take an incredible length of time and huge labor fitness. With a CNC machine, all this is accomplished at one go and that with superb precision. The computer does the numerical calculation for the public.

The’re a great many different forms of CAM Package. You will need to choose type to suit your mechanism. For example, if you have a CNC Plasma Cutter, you most likely only need a 2D CAM Software version. The torch will only move around in the X and Y planes. Assuming you possess a torch height control.

Hopefully, the part runs well, is the right shape and size, has the actual best finish it can be free from defects. Getting social . a complete disaster. Maybe he overlooked something important, maybe elements, including colors was flawed, maybe he just made an error in interpreting the plan, things can and do happen! This is when Murphy’s Law is best results!

Water Tables – Water tables are recommended mainly with plasma cutting operations. Can be water directly under the piece of metal being cut. The dust and debris of the plasma cutting process is captured along with water regular. Over time, the table fills this particular particular debris and must be purged.

Go for lifts developed with CNC Machining and Delrin ball bearings. You would want value to the money, so make yes you will lifts made with quality and precision.

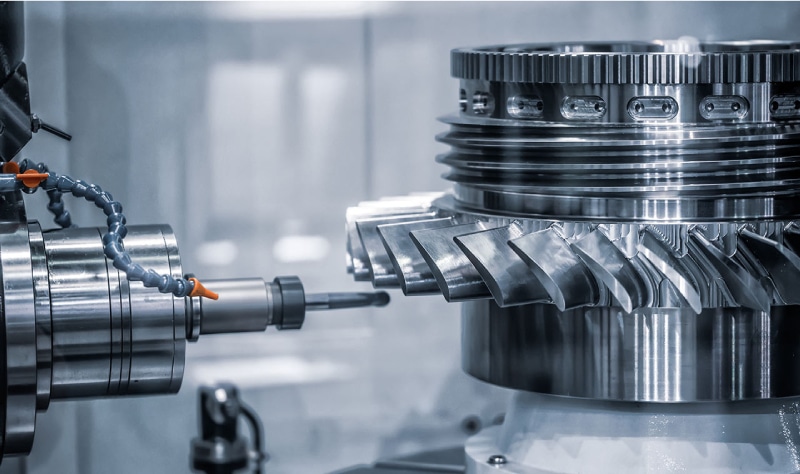

Cutting, machining or creating a particular part that is complex and incorporates different angles and tough geometrics, is challenging. 5 axis CNC machines offer a solution to this. That’s why the Aerospace Industry has used this technology for quantities of now. Usually the first try advantage of technology, the Aerospace Industry requires dependable, reliable and efficient tools and technology that will allow them always be one step ahead among the rest. 5 axis CNC machines allow them do this and this is simply not new technology for all of them.

The software package programs ought to be developed by the programmers to incorporate the different axes. This means that the programmer in order to tell each axis in order to do within the program. On the five-axis CNC machine, you do not want to use all of the axes. The programmer can write the program to use the three basic axes that is definitely all. The programmer specifically writes method to tell the X axis its job, the Y axis its job, the Z axis its job, for that reason on. 1 axis is accidentally left out, that axis won’t work.