Welcome to the world of valves and controls, where precision and reliability are paramount in ensuring the seamless operation of various industrial processes. Valves play a crucial role in regulating the flow of liquids, gases, and other substances within pipelines and systems. When combined with advanced control mechanisms, these components become the cornerstone of efficient and sophisticated automation systems.

Valworx stands out as a trusted partner in this realm, with its ISO 9001 certification affirming its commitment to quality and excellence. By offering a diverse range of actuated valves and controls, Valworx caters to the unique needs of the industrial, institutional, and government sectors. With a streamlined process that includes in-house assembly, rigorous testing, and same-day shipping, Valworx ensures that its customers receive prompt and reliable solutions tailored to their specific requirements.

Types of Valves and Their Functions

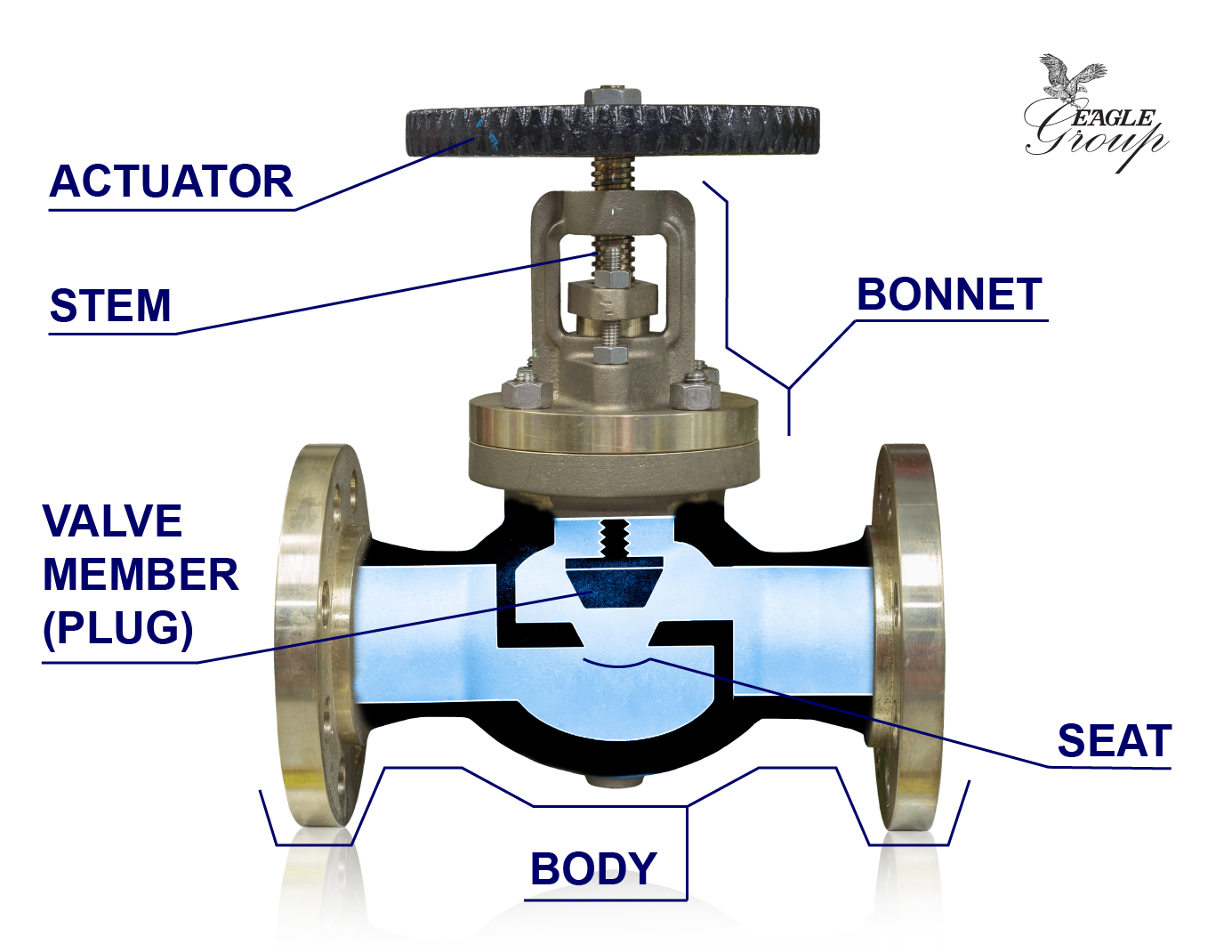

Valves are essential components in a wide range of industries, providing control and regulation of fluid flow within systems. Globe valves, for example, are commonly used to start, stop, and regulate flow, making them versatile for various applications. Ball valves, known for their quick quarter-turn operation, are suitable for shutoff applications where tight sealing is required. Meanwhile, butterfly valves are lightweight and ideal for applications with large pipe diameters, providing efficient flow control.

Gate valves are designed for on/off service, offering low fluid resistance when fully open. Check valves, also known as non-return valves, allow flow in one direction only to prevent backflow. Pressure relief valves are crucial for protecting systems from overpressurization, opening to release excess pressure and ensuring safety. Each type of valve serves a specific function and plays a critical role in maintaining optimal system performance.

Benefits of Using Actuated Valves

Actuated valves provide automated control, allowing for precise and efficient regulation of fluid flow in various industries. By utilizing actuated valves, companies can improve operational efficiency and reduce the need for manual intervention. This leads to enhanced productivity and process consistency.

Another key benefit of actuated valves is the ability to remotely monitor and control valve functions. This feature enables operators to make adjustments from a centralized location, improving safety and reducing the risk of human error. Additionally, actuated valves offer quick response times, ensuring rapid adjustments to changing system conditions.

Actuated valves also contribute to cost savings by minimizing downtime and maintenance requirements. With their reliable performance and automated functionality, these valves help optimize processes and prevent issues that could result in production losses. Overall, the use of actuated valves is integral in achieving operational excellence and maximizing operational output.

Important Considerations for Valve Control Systems

When designing valve control systems, it is crucial to consider the specific requirements of the application. Factors such as the type of fluid being controlled, pressure levels, temperature variations, and flow rates must all be taken into account to ensure optimal valve performance and longevity.

Butterfly valve with manual lever operator

Additionally, the selection of the right valve type is essential for efficient control. Ball valves, butterfly valves, gate valves, globe valves, and solenoid valves each have distinct advantages and limitations depending on the application. Choosing the correct valve type based on factors such as flow control precision, pressure drop, and maintenance requirements is key to achieving desired operational outcomes.

Lastly, regular maintenance and monitoring of valve control systems are paramount. Periodic inspection of valves for leaks, corrosion, and wear can prevent costly downtime and potential safety hazards. Implementing a proactive maintenance schedule, along with proper training for personnel on valve operation and troubleshooting, can significantly extend the lifespan of the system and maximize overall efficiency.